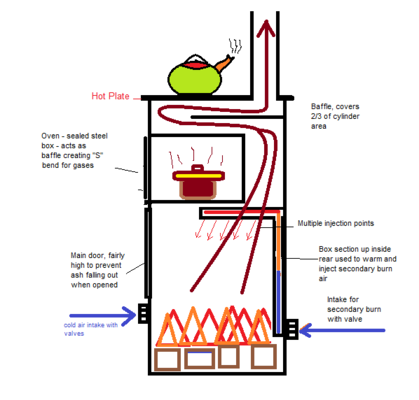

Secondary burn or combustion on a wood stove is the process of burning off waste gases higher up in the stove in order to produce more heat and to reduce emissions.

Adding secondary burn to wood stove.

Lower part it would certainly help to keep the temperatures high.

The tubes run up the sides of the stove.

That gradually stops when the wood becomes more charcoal like and burns with less flames.

2 the secondary air you are looking for will only work well if you burn dry wood.

This is a project to increase the efficiency of an older but still very serviceable wood burning stove.

Currently the sides and back are insulated.

Secondary burn is a feature incorporated in the majority of new wood burning stoves.

The secondairy burn is mostly used in the first phase of a new log.

Here goes to achieve secondary burn 1 you need a good amount of heat in your stove and good coals.

It is sometimes referred to as a clean burn clean burning stove or tertiary air all of which mean a reduction in emissions and an overall improved efficiency.

How secondary combustion in a woodstove works.

Maybe i should also add some insulation tiles to the baffle plate.

Scott also goes through a method for actually measuring the efficiency of a wood stove using just a wind meter and a thermometer.

Then it enters the front of the stove over the fire is routed through solid pipe to the rear of the stove for preheating and then is dumped into the top of the burn area just under the baffle through the holes drilled down the length of the burn tubes.

Stove world uk explains why a woodburning stove with secondary burn is so good.

A second feed of air over the fire in a wood stove firebox helps secondary burn to occur.

I have a vogelzang mountaineer wood stove non catalytic steel box lined with firebrick steel baffle above fire and air intake above glass viewing door.

To achieve the secondary burn you will need secondary air.

Clear benefits of secondary combustion are increased heat output with less wood lower emissions and decreased creosote formation.

Secondary air can be controlled from the gate valves and shut off if there were ever a chimney fire.

With secondary combustion systems for wood stoves this secondary heat can be used to add additional heat energy to the primary heat.

Scott added an air supply for secondary combustion and retrofitted a catalytic combustor.